Case Study On Detention Of Ships Relating To GMDSS Radio Equipment

The primary purpose of GMDSS is to ensure distress alerts are effectively broadcasted and received. The system automates and improves emergency communication from ship to ship, ship to shore and shore to ship, as well as the receiving of important navigational and safety messages. To ensure this vital piece of equipment is operationally ready, the equipment should be regularly tested based on the functional requirements documented in SOLAS IV/Regulation 4. GMDSS radio installation has been receiving attention from Port State Control Officers, particularly in aspects such as the operators working knowledge, familiarisation, training and maintenance of the on-board radio installation and arrangements. 10 Singapore flagged vessels were detained between 2013 and 2015 due to GMDSS deficiencies related to VHF, MR/HF, NAVTEX, SART, EPRIB and emergency sources of energy. In 2016, there was 1 GMDSS-related detention. However, for the first half of 2017, we have already seen 2 cases of GMDSS-related detention. Common deficiencies include:- GMDSS batteries (reserve source of power) not being operational

- Crew unable to demonstrate operation of MF/HF radio on DC power

- VHF telephone DSC test defective

- GMDSS equipment (Main MF/HF Trans-Receiver Unit) not working on emergency power supply

- MF/HF found defective

- NBDP found defective

Case Study for MF/HF Radio Installation

We have been issuing numerous deficiencies relating to MF/HF Radio Communication during our flag state control inspections. These are also common deficiencies issued by Port State Control Inspectors and it appears there is a general lack of awareness on the operation, maintenance and testing of the MF/HF installation.

To better understand and identify the underlying causes of deficiencies relating to MF/HF installation, and the appropriate corrective actions to prevent recurrence, let us look at one of the detention cases.

After 2 weeks of waiting at the outer anchorage of the loading port, the vessel was subjected to a Port State Control inspection upon berthing. The crew was asked to demonstrate operation of the MF/HF equipment on the emergency power source. The crew switched off the main power supply and immediately, the Port State Control inspector noticed the voltage gauge on the panel had dropped to 20 volts. The crew tried numerous time to operate the MF/HF equipment, alternating between main and emergency power sources. However, all attempts were unsuccessful.

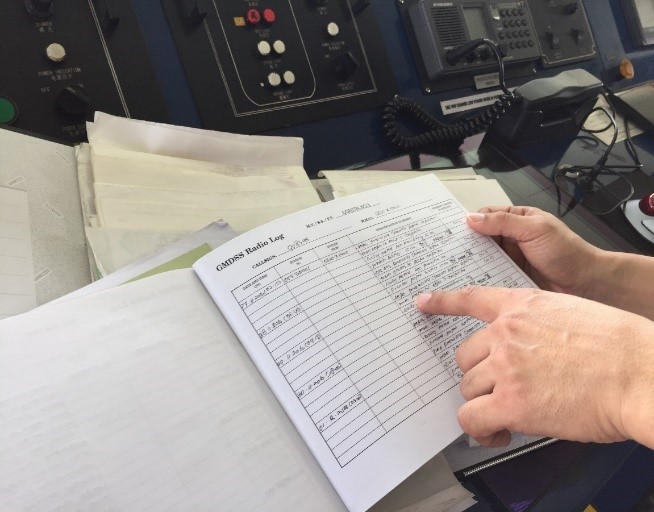

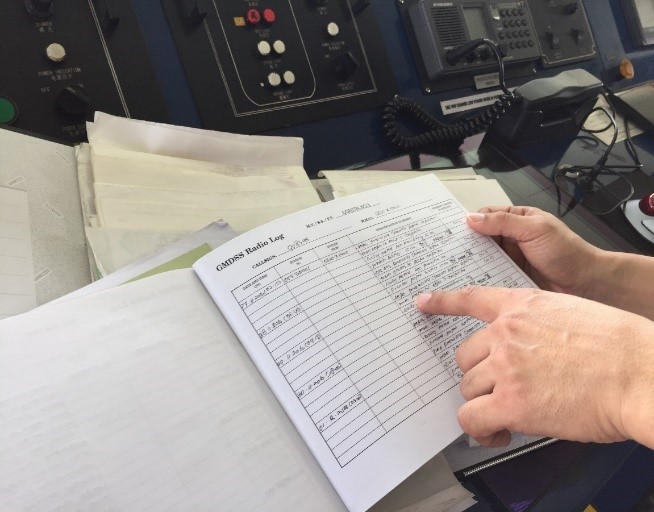

The GMDSS logbook was subsequently scrutinised by the Port State Control inspector. There was no evidence to prove that the MF/HF DSC weekly test with the nearest coast station had been conducted as required.

When asked about the apparent absence of proof that the mandatory weekly tests of the MF/HF had been carried out, the crew insisted they had indeed been carried out but not recorded. The crew added the required tests were carried out whilst the vessel was anchored at the outer anchorage and despite numerous attempts, there was no reply from the coast station.

The Port State Control inspector after checking with the crew which coast station the test message was sent to, verified with the relevant MRCC and confirmed no MF/HF DSC test messages were received by the coast station. The Port State Control inspector concluded the MF/HF installation was defective and detained the vessel.

No record in the GMDSS log book for daily/weekly tests

Reserve battery defective i.e. reading indicate less than 24V

Underlying Causes of Deficiencies

- Lack of clear work instructions and procedures provided by the company to guide Master and officer-in-charge on tests and checks of MF/HF resulted in the following:

- Inadequate instruction in PMS for tests/checks and maintenance of MF/HF

- Inadequate instruction in PMS for tests/checks and maintenance of Reserve source of energy (battery).

- The Master and navigation officers were not familiar with the testing, checking and maintenance of the GMDSS installation.

- Lack of planning, supervision and oversight by senior ship's officers and the company.

Simple and Actionable Corrective Actions

Getting the job done right the first time and every time!

- Establish clear, adequate and specific procedures, work instructions and checklists to control the inspection, testing and maintenance of the GMDSS installation, including antennas, mountings, cables and connections.

- Establish clear, adequate and specific procedures and checklists to control the inspection, testing and maintenance of the emergency power source.

- Review and improve the familiarisation programme for the crew, and recognise the GMDSS installation is a vital shipboard emergency communication equipment which is regularly subject to control by the flag and port states.

- Review the job description of senior ship's officers to ensure they maintain proper supervision and oversight of the mandatory tests, routine checks and maintenance of MF/HF installation onboard their ships.

- MF/HF testing procedure to include contacting the coast station to confirm the receipt of the transmission test call if no response is received from the coast station.

References:

- SOLAS Chapter I, regulation 11(c) - Reporting of defects which affect the safety of ship to the flag Administration, Recognised Organisation and appropriate authority of the port State

- SOLAS Chapter IV, Regulation 1, 4, 7, 8, 9, 10, 11, 13, 15

- COMSAR/Circ.32, para. 1.6

- IMO Resolution A.702 (17)

- ISM Code, section 6 (Resources and personnel) and section 10 (Maintenance of the ship and equipment)