Unsafe act and ignoring personal safety are common human errors that can lead to incidents onboard. Here are 3 case studies where unsafe act and/or condition during course of work on board has led to adverse consequences.

Case Study 1 - Electrician fall to his death

A container ship was conducting cargo operation and the quay crane was working on containers in the cargo hold with hatch covers removed.

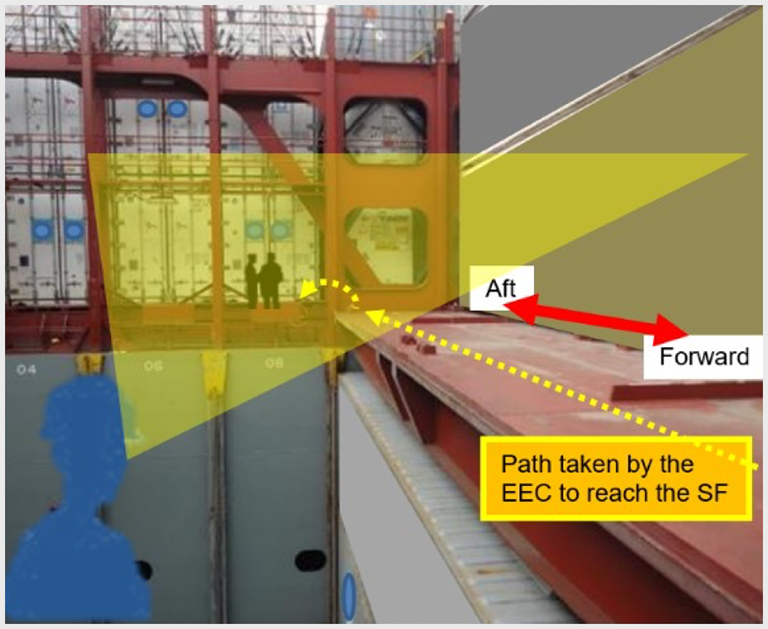

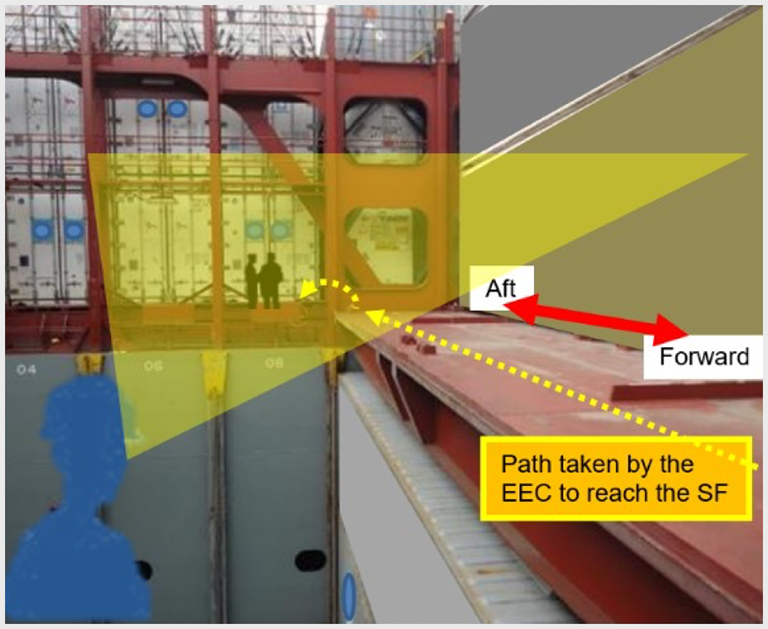

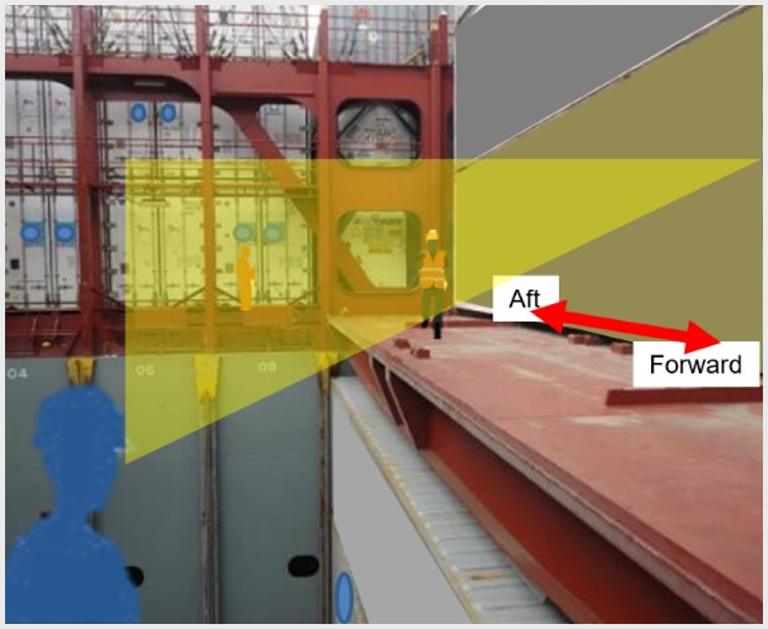

Figure 1

The electrician (EEC) had requested the shore foreman for assistance to address issue they encountered with some of the reefer containers on board.

The electrician, seeing that the foreman was just across the cargo hold, decided to walk on the hatch cover of the partially open hold to reach him (See Figure 1). The third officer who saw this unsafe act did not react but instead waited for the electrician to return.

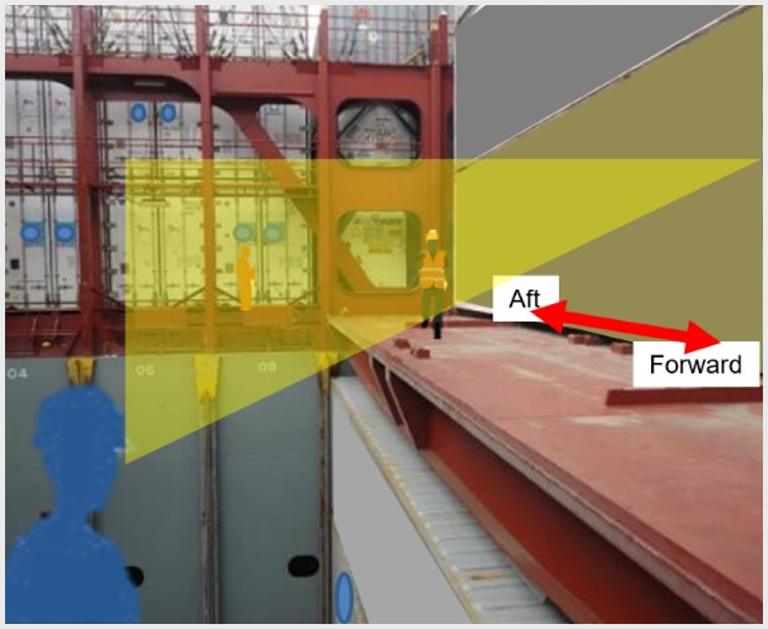

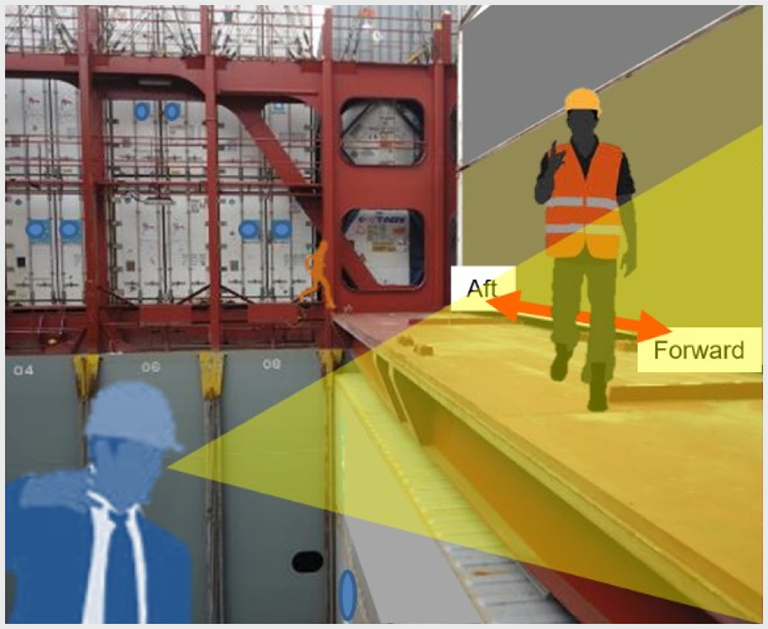

Figure 2

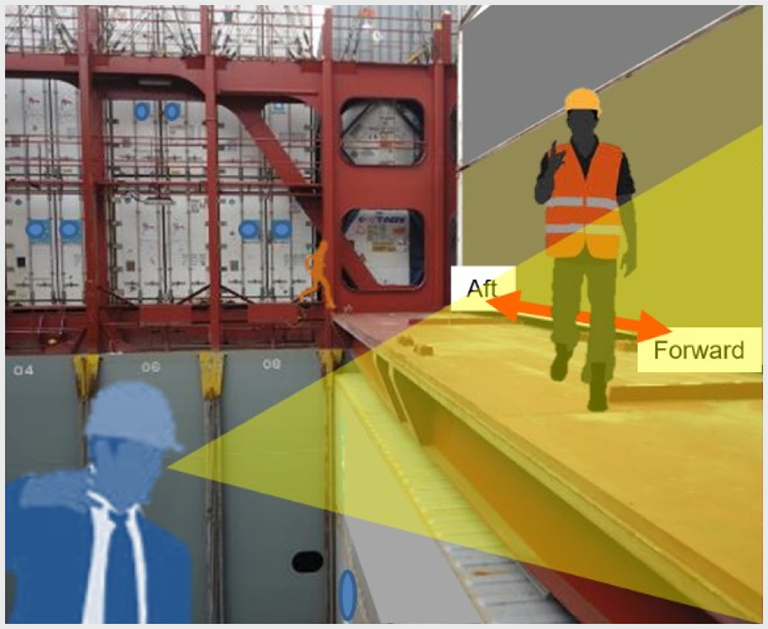

Figure 3

While the foreman made his way to the third officer, the electrician was still on the crossdeck of the cargo hold (See Figure 2). Both the foreman and third officer had their backs towards the electrician as they were looking at the faulty reefer containers (See Figure 3).

A sudden loud boom was heard, and when the third officer and the foreman turned, the electrician was seen inside the cargo hold. The electrician had fallen 20 meters into the cargo hold.

Lesson learnt

The unsafe act of crossing over an open hold had cost the electrician his life. The third officer could have intervened the unsafe safe act by stopping. This incident serves as a reminder that safety is everyone's responsibility; one who sees an unsafe act or an unsafe condition has the responsibility to act upon it and advise each other, before tragedy strikes.

Case Study 2 - Third engineer injured during rounds

A general cargo ship was on a voyage from Brazil to Spain and the ship was off the Spanish coast and steaming to moderate seas. Third engineer was doing his rounds in the engine room when he spotted oil droplets near a flywheel (See Figure 4). He then went on to clean the oil with a rag that he had with him (See Figure 5).

Figure 4

Figure 5

As he was cleaning the oil, the rag together with his hand got caught into the rotating flywheel. He moved his hand away immediately, but his left index finger hit the flywheel cover in the process and suffered a deep cut.

Lesson learnt

The unsafe act of placing the rags and his hand close to a rotating flywheel had caused a simple cleaning task to result in an injury. This could be prevented if he had followed the company's lock-out system and stop the auxiliary engine before commencing work in the area of the rotating flywheel.

Case Study 3 - Oiler injured during maintenance work

A container ship was in port at Houston, USA when maintenance works on the main engine was carried out. Third engineer and oiler were tasked to work on the main engine unit No. 4 cylinder head. They had to remove the cylinder cover and stow the spacer ring onto its stand.

Whilst stowing the spacer ring, the oiler's fingers (ring and middle) got caught between the spacer ring hole and the base of the stand (See Figure 6).

Figure 6

Lesson learnt

The lack of attention by the oiler during the stowing of the spacer ring had caused this injury. An experienced fitter who is familiar with the mechanics should be assigned to avoid such incident.