Case study: Crew crushed by falling steel plate

What happened?

While shifting a steel plate that was stored in the steering gear room, an engine crew died when the said plate fell and crushed him

Why did it happen?

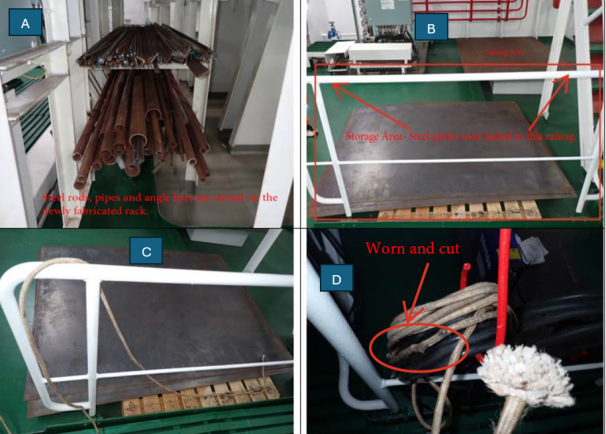

A vessel was on her maiden voyage from building yard. Many repair materials were supplied on board which were intended for use by the crew on board to fabricate additional storage boxes and tools. These materials were stored by ship’s crew in the steering gear room. Steel rod, pipe and angle bars were stored on the newly fabricated storage rack (see A in Figure 1) while the steel plates were lashed to the handrail with a 10mm nylon rope (see B, C and D in Figure 1).

On the day of the incident while the vessel at sea, two Senior Engineers attempted to reposition a 5mm steel plate in a stowage area prior to bringing it to the nearby cutting area (see image B in Figure 1 and image 1 in Figure 2). A Junior Engineer (JE) was tasked to hold onto other vertically leaning plates that were supported against the railing to prevent them from falling.

While holding on to the vertically leaning plates, the JE was instructed by one of the Senior Engineer to assist with shifting the 5mm steel plate since it was too heavy for both Senior Engineers to move. The JE released the vertically leaning plates he was holding onto and squatted down to help lift the 5mm plate (see image 3 and 4 in Figure 2). At that moment, a sudden vibration of the vessel occurred, causing those leaning steel plates to fall onto the EC (see image 4 in Figure 2).

Conclusion

Unsafe Storage and Lashing of Steel Plates

The steel plates were stored vertically and leaning against a collapsible handrail and secured with a nylon rope of 10 mm in diameter. The handrail was not designed for storing steel plates. It is neither an appropriate location nor a proper method to store them. In addition, the 10mm nylon rope that was used to lash those plates was found to be in poor condition. The condition of the rope was a persistent risk during plate handling and securing when it parts.

Inadequate Risk Assessment (RA)

The RA for the above work activity was found to be generic and inadequate. Essentially, the RA did not identify the hazards associated with falling steel plates or the risk of injury resulted from sharp edges. At the time of the incident, the ship was pitching, and the motion increased the likelihood of the leaning plates to fall. While the JE was holding onto the remaining vertical plates, the Senior Engineer requested him to assist on shifting the 5mm steel plate. The Senior Engineers had omitted consideration of the JE’s safety in relation to the risk of steel plates falling in view of the ship’s pitching and rolling motions.