The Singapore Flag's Performance in the 3rd Quarter of 2015

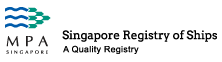

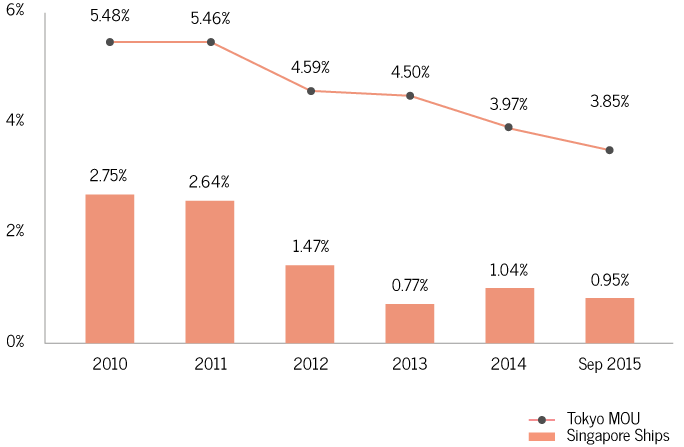

In the first three quarters of 2015, Singapore ships performed better under Port State Control (PSC) in the Tokyo MoU regime than in the Paris MoU regime.

- Tokyo MoU regime – the detention ratio of Singapore ships is 0.95% against the regime’s average of 3.85%.

- Paris MoU regime – the detention ratio of Singapore ships is 2.14% against the regime’s average of 3.19%.

The SRS performance under the Tokyo and Paris MoU regimes over the past six years are illustrated in Figure 1 and 2 below.

Tokyo MOU Detention Ratio

Paris MOU Detention Ratio

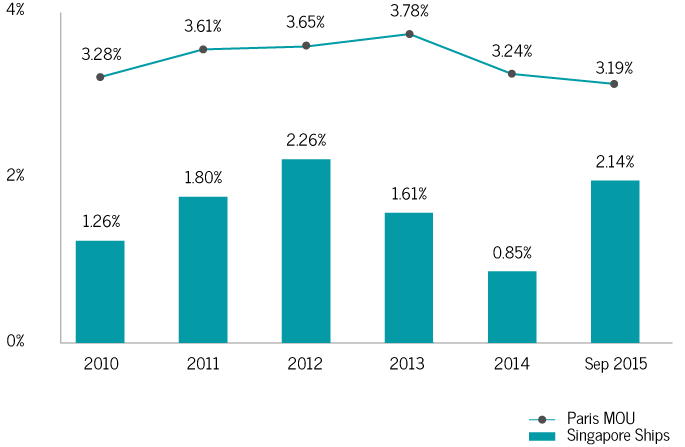

A significant number of Singapore ships are still being detained in Australia and the United States, representing more than 55% of Singapore ship detentions this year. The detentions were due to common detainable deficiencies, which will be highlighted in the next section. The breakdown of Singapore ship detentions by Port States is given in Figure 3 below.

PSC detention of Singapore ships by Port States - 3Q of 2015

Most Common Causes of Ship Detentions

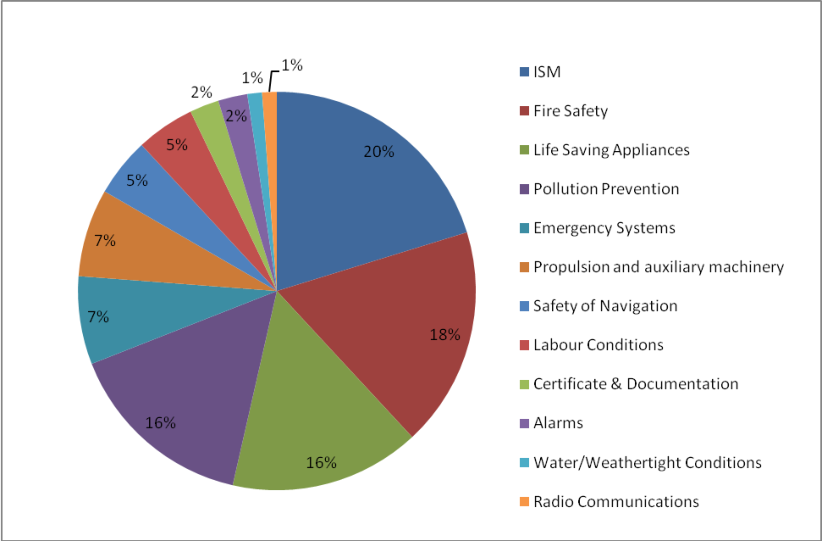

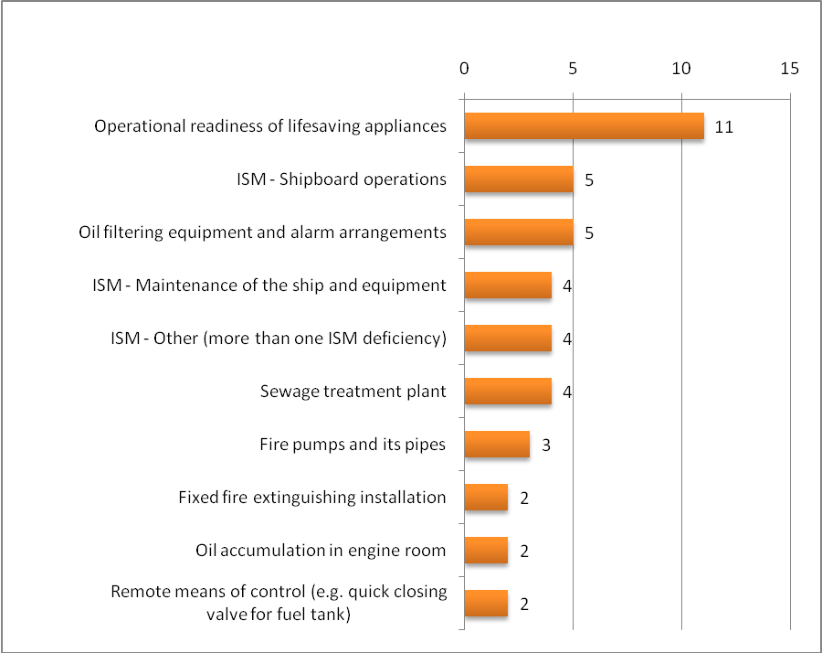

From the analysis of Singapore ship detentions, the four most common categories of PSC detention deficiencies are ISM-related, Life Saving Appliances, Fire Safety and Pollution Prevention. These categories make up 70% of the total detention deficiencies. Under these four categories, the commonly recurring PSC detention deficiencies are summarised as follows:

- ISM-related:

- Inappropriate voyage planning and use of inadequate or outdated nautical charts

- Inadequate management and recording of seafarers’ hours of rest

- Poor maintenance of safety and critical shipboard equipment

- Fire Safety:

- Emergency fire pump unable to build up sufficient water pressure in the fire mains

- Defective quick closing valve for fuel tank

- Life Saving Appliances:

- Lifeboat and rescue boat engine unable to be started

- Defective lifeboat and rescue boat launching arrangement

- Pollution Prevention:

- Defective oily water separator and 15ppm alarm arrangements

- Defective sewage treatment plant

The breakdown of all the PSC detention deficiencies found on Singapore ships in the first three quarters of 2015 are given in Figure 4 and 5 below.

Detention deficiencies by category - 3Q of 2015

Top 10 detention deficiencies - 3Q of 2015

Ship owners, companies and crews are strongly encouraged to pay close attention to the underlying causes of the common deficiencies that have been highlighted above and take necessary preventive actions. This should include ensuring their crew are provided with adequate procedures, work instructions and tools to carry out their work effectively, and the work are properly supervised by senior ship officers, especially for the inspection, testing and maintenance of safety and critical shipboard equipment (e.g. lifeboat engine, emergency fire pump, oily water separator, sewage treatment plant, emergency generator etc).

Case Study - Fire Safety on Ships

The SOLAS Convention requires ships to have safe design and fire safety systems to prevent, contain, control and suppress fire or explosion, and to reduce the risk to life and damage to the ship and cargo caused by fire. This includes:

- Dividing the ship into main vertical and horizontal zones by thermal and structural boundaries

- Restricted use of combustible materials

- Detection of fire in the zone of origin

- Containment and extinction of fire in the space of origin

- Safe means of escape and access for fire fighting

- Ready availability of fire-extinguishing appliances

To ensure the effectiveness of these fire safety measures, vital fire protection and fire-fighting systems and appliances must be properly and regularly inspected, tested and maintained in good working order and kept ready for immediate use at all times.

During Flag State Control (FSC) and Port State Control (PSC) inspections, close attention is paid to ensure the good working order and operational readiness of fire protection systems and appliances on board ships. Common deficiencies found during inspections include defective quick-closing devices for oil tanks, engine room ventilators, fire dampers, jacketed high-pressure fuel lines and insulation of engine exhaust pipes.

In this issue, we will specifically focus on the importance of ensuring the good working order of quick-closing valves for engine room fuel oil tanks.

SOLAS Regulation II-2/4.2.2.3.4

Oil fuel pipes, which, if damaged, would allow oil to escape from a storage, settling or daily service tank having a capacity of 500L and above situated above the double bottom, shall be fitted with a cock or valve directly on the tank capable of being closed from a safe position outside the space concerned in the event of a fire occurring in the space in which such tanks are situated.

Common deficiencies related to fuel oil quick-closing valve system

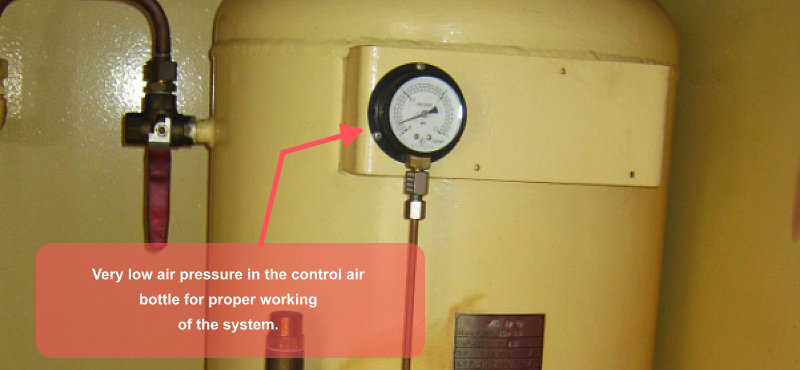

- In air-operated systems, the control air bottle is either kept empty or at very low pressure, rendering the system inoperable

- In hydraulically-operated systems, minor oil leakage in the system prevents sufficient oil pressure to be built up to close the quick-closing valve

- For cable-operated systems, the actuating cable for the quick-closing valve is badly maintained or in poor condition, causing the cable to snap when it is pulled

- The control air or oil pilot line is blanked off or disconnected, rendering the quick-closing valve inoperable

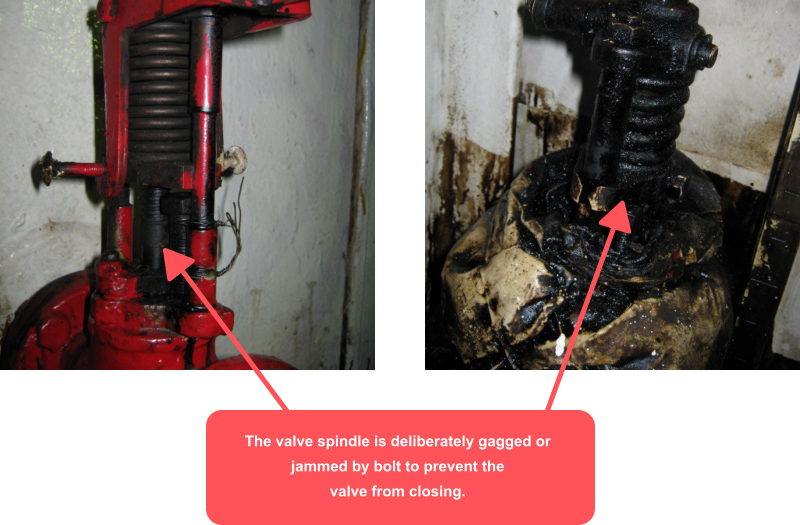

- The quick-closing valve is deliberately gagged or jammed to prevent it from closing

These photographs illustrate the above deficiencies:

The quick-closing valve system for oil tanks is a vital component of shipboard fire fighting systems. It serves to cut off the supply of flammable oil in case of a fire in the engine room. The system must be properly inspected, tested and maintained to ensure that it can function as intended in times of emergency.

Often, the ship’s crew are hesitant to test the system due to unfounded fear that it may cause a black-out on board. This may even cause the crew to deliberately jam and disable the quick-closing valves. This defeats the purpose of the quick-closing valve system and the capability to contain and control a real fire on the ship.

The ship’s crew should understand that running engines will not stop immediately when the quick-closing valve for the fuel oil service tank is closed momentarily. There is sufficient fuel oil circulating in the system to keep the engines running for a while. Therefore, testing of the system can be safely carried out by resetting the quick-closing valve promptly after the test.

Underlying causes of the deficiencies

- Ship’s crew members are not familiar with the SOLAS requirements or the intent and purpose of the quick-closing valve system

- Lack of confidence in skill/experience to test the system due to fear of causing a black-out on board

- No clear procedure or work instructions to ensure proper inspection, testing and maintenance of the system

- Inadequate supervision by senior officers

Simple and actionable corrective actions

- Company could review existing shipboard practices with regard to testing of the quick-closing valve, and correct any improper testing method on board their fleet

- Company and vessel’s Safety Management System (SMS) should provide specific measures for proper and regular inspection, testing and maintenance of fuel oil quick-closing valve systems on board

- Provide proper familiarisation training to the ship's crew on the proper inspection, testing and maintenance of the quick-closing valve system

- Simple work instructions for testing and resetting of valves can be posted at the vicinity of the equipment for the crew’s easy reference

- Senior officers to supervise the work carried by junior officers to ensure proper standards

In Closing...

Ship owners and companies need to allocate adequate resources to ensure the inspection, testing and maintenance of shipboard fire fighting AND fire prevention systems are properly carried out by responsible ship personnel under adequate supervision of senior officers. This is for the purpose of safety of the vessel and crew.

References:

SOLAS Chapter II-2, Construction – Fire Protection, Fire Detection and Fire Extinction

ISM Code, Section 8 (Emergency Preparedness) and Section 10 (Maintenance of the ship and equipment