Lessons Learnt: Unsafe Act-Unforgiving Shortcut

What Happened?

During a routine cargo operations onboard a feeder container ship, i.e. loading and discharging of containers, the designated crew member (wireman) who was tasked with the plugging in of refrigerated (reefer) containers onboard was subjected to an electric shock which proved fatal. The incident took place at night and the ambient weather was wet. The wireman had joined the ship 10 days prior to the incident.

Why Did It Happen?

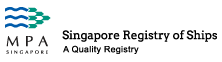

Investigations into the incident revealed that the electrical reefer socket [Make: Kokosha] in use at the material time was damaged internally. The faulty socket did not allow for a proper electrical connection to be made between the plug and the socket.

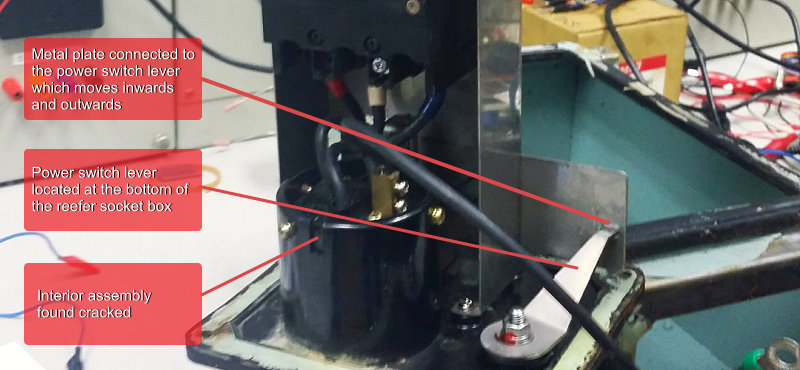

When the compressor for the reefer container did not start, the wireman presumed there was a possible fault with the safety interlock which was not being lifted by the plug, when the power switch was in the “On” position. The access to the safety interlock was behind the socket.

In his attempt to by-pass the safety interlock, the crew member accidentally inserted a screwdriver into the reefer socket. Wet ambient conditions caused the current flowing through the ship’s power supply (440V) to the reefer socket into the crew member’s body, causing his death due to a heart attack.

Safety Issues

- Although the company's Safety Management Systems provided for routine tests on the reefer sockets, these checks were limited to electrical conductivity tests and did not cater for the physical inspection of the sockets to check for physical damage

- The crew member did not inform his superior to determine the cause of the problem. He performed an unsafe act to by-pass the safety interlock

- The autopsy revealed that the Blood Alcohol Content (BAC) of the deceased was 90mg/100ml, more than 3 times the limit prescribed in STCW Convention and the company's Drug & Alcohol Policy.

Safety Recommendations

While the work done was routine and possibly performed many times by appropriately qualified crew, all seafarers should note the dangers in handling electrical equipment. Shipping companies and ship’s crew are recommended:

- To review ships' Safety Management Systems to ensure there are clear instructions not to by-pass safety mechanisms and safe work procedures are followed when operating electrical equipment in wet weather conditions

- To enhance the inspection and maintenance regime within the company's Planned Maintenance System (PMS) for reefer sockets

- Review the enforcement of company's Drug & Alcohol Policy