The Singapore Flag Performance in the 1st Half of 2015

In the first half of 2015, Singapore ships performed relatively well under Port State Control (PSC). However, many Singapore ships are still being detained in Australia and the United States due to common detainable deficiencies.

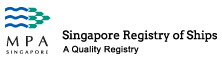

Tokyo MOU Regime

The detention ratio of Singapore ships in the first half of 2015 was 0.84% against the regime’s average of 4.08%, an improvement compared to 2014’s detention ratio. A majority of the detentions on Singapore ships took place in Australia.

Tokyo MOU Detention Ratio

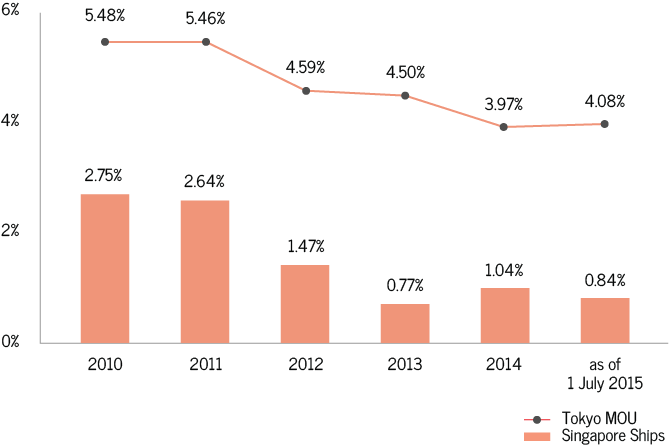

Paris MOU Regime

The detention ratio of Singapore ships in the first half of 2015 was 1.95% against the regime’s average of 3.05%, a significant increase compared to 2014’s detention ratio, primarily due to the detention of 6 Singapore ships against a low number of inspections.

Paris MOU Detention Ratio

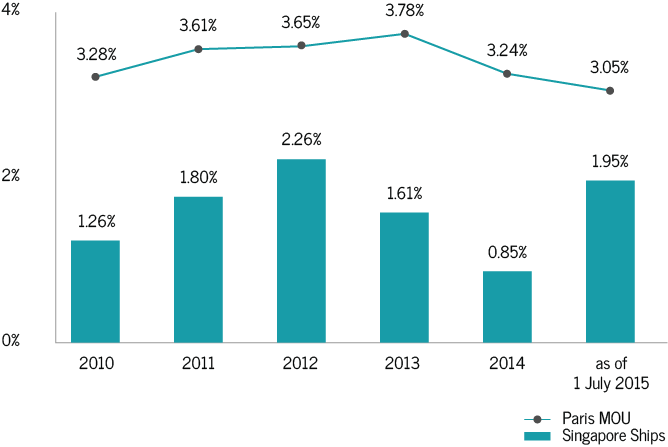

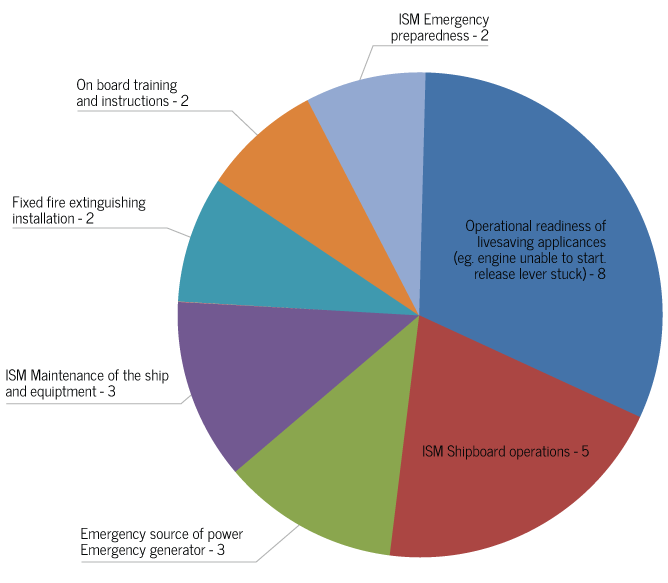

Most Common Causes of Ship Detentions

As evidenced by the detentions of Singapore ships in the first half of 2015, a majority of the detentions are still caused by the same categories of deficiency, namely ISM–related, Life Saving Appliances, and Fire Safety. The ISM–related deficiencies mainly refer to the poor maintenance of safety and critical equipment, emergency preparedness, and shipboard operations (e.g. passage planning, rest hour management). There has also been an increase in the number of detentions due to the inability to start (by any means) the emergency generator.

Detention deficiencies by group deficiency – 1st Half 2015

Detention deficiencies by specific deficiency – 1st Half 2015

MPA Dialogue Session with Shipping Companies

As part of MPA’s continual effort to improve the performance of the SRS, the Flag State Control (FSC) Department held two dialogue sessions on 28 and 30 April 2015 with about 70 DPAs and technical managers/superintendents from 32 companies. The sessions targeted owners/companies managing Singapore ships that trade in the United States and Australia, where the SRS is experiencing higher Port State Control (PSC) detention rates.

During the sessions, participants were briefed on the SRS’ performance in 2014 and 2015, and statistical trends and case studies of PSC detentions involving Singapore ships. The sessions also discussed how companies could relate to PSC deficiencies in terms of inadequacy or breaches of “barriers/defences” in companies’ Safety Management System (SMS). The participants were also acquainted with methods and tools (e.g. process-based approach, loss causation model) used by FSC surveyors to investigate and analyse PSC deficiencies and draw on lessons learnt to improve the standard and implementation of companies’ SMS.

Companies engaged in brainstorming session

In the final segment of the sessions, participants were broken up into groups to analyse common PSC detention cases, using the tools that have been shared with them, to brainstorm for possible underlying causes of detention deficiencies and appropriate corrective actions that could be implemented to improve relevant work processes and routine activities on their ships.

MPA will be conducting more of such sessions in the coming months. Shipping companies will be contacted accordingly.

Detention Case Study – Safety of Navigation

The primary responsibility of Masters is to ensure the safety of navigation during the voyage. To ensure safety of navigation and protection of the marine environment, Masters should make sure that appropriate nautical publications are used, navigational systems and equipment are working properly, officers are competent and voyage is properly planned, executed and monitored.

The following is an example of a port State control inspection of a ship by MPA or other port authority to illustrate some of the typical deficiencies on a ship related to navigation safety.

Vessel “ABC”, anchored in port waters, was boarded by a PSC officer. The PSC officer commenced his inspection with an opening meeting, followed by the verification of vessel and crew documents. Thereafter, he proceeded to the wheelhouse to assess the crew’s performance with regard to safety of navigation. First, he inspected the charts and publications. Next, he questioned the officer-in-charge on issues relating to passage planning. Finally, he inspected the navigational systems and equipment on board.

The PSC officer’s findings are summarised below:

Charts and Publications

Latest edition of nautical charts and publications (e.g. tide table, sailing directions) for the intended voyage are not available on board. Ship staff is still using outdated charts and publications.

Nautical charts used for the intended voyage were not updated with Chart Corrections and Temporary & Preliminary Notices (T&P).

Adequate charts (e.g. large scale charts) for the intended voyage are not available on board. A photocopied (i.e. not original) chart was used instead.

Passage Plan

Passage plan prepared by ship staff was incomplete (e.g. passage plan did not cover from berth to berth).

Inadequate position fixing on charts. No positions recorded in GPS log book/position fixing book throughout the entire voyage.

Monitoring of passage plan was not done using the primary means of navigation.

Navigational Systems and Equipment

Several critical navigational equipment were non-operational or not fully operational (e.g. speed log, gyro compass, radar and magnetic compass without deviation card).

At the end of the inspection, the PSC officer handed the Master a list of deficiencies, largely related to safety of navigation and the ship was detained.

Based on earlier experiences, the possible underlying/root causes of deficiencies related to safety of navigation include the following:

Lack of clear shipboard procedures, work instructions and checklists provided by the company to guide the Master and officer-in-charge in the following:

Preparing of passage plan (e.g. passage plan format and checklist);

Maintenance of charts, publications and navigational equipment;

Requisition of latest editions of nautical charts and publications.

Inadequate procedures by the owner/manager to promptly provide the latest edition of charts and publications to ships.

Lack of motivation by ship staff in the preparation and monitoring of passage plan:

Ship staff treats passage planning as a “tick-box” exercise, only doing the necessary paperwork without actually verifying the requirements in the passage plan (e.g. ship staff ticks the checkbox stating that charts for the intended voyage are updated, without actually updating the charts);

Over-reliance on electronic navigational equipment (e.g. GPS, unapproved ECDIS meant for training purposes) by Officer-On-Watch (OOW) during voyage, without complying with SMS procedures relating to the monitoring of passage plan (e.g. regular position fixing on charts).

Lack of skill/experience by ship staff when preparing passage plan, resulting in missing information and passage plan not meeting work standards.

Inadequate supervision by the Master.

Masters and navigating officers are reminded that:

Shipboard operations, including the preparation and monitoring of passage plan, should be based on risk assessment as required by ISM Code. This is to ensure that all identified risks are mitigated with control measures to an acceptable level, in order to achieve safe passage.

SOLAS requires adequate and up to date nautical charts and publications for the intended voyage(s) to be provided on board [SOLAS regulation V/27] and proper passage planning for the entire intended voyage (i.e. berth to berth) [SOLAS regulation V/34 and IMO Resolution A.893 (21)].

Navigational systems and equipment should be fully operational [SOLAS regulation V/19]. Furthermore, any defects in the equipment should be promptly reported to the Administration and the appropriate authorities of the port State [SOLAS regulation I/11(c)].

Simple and Actionable Corrective Actions

Company

Company should have clear navigation policies, procedures, work instructions and checklists relating to the importance, requirements and expectations of passage planning, monitoring of passage and maintenance of charts, publications and navigational equipment on board.

Company should periodically review and update their SMS to ensure compliance with SOLAS requirements whilst taking into account IMO guidelines and recommendations relating to the safety of navigation.

Company should provide clear instructions and responsibilities to the Master in ensuring safe passage and the implementation/enforcement of company SMS on board.

Company should conduct pre-joining briefings to all new navigation officers, familiarising them with the company’s expectations, instructions and work standards with regard to the preparation and monitoring of passage plan.

Company should establish a system to monitor the validity of charts and publications on board their ships, so as to provide the latest edition of charts and publications to the ships in a timely manner.

Company should verify the vessel’s compliance with company’s navigation policies and SMS during shipboard internal audits.

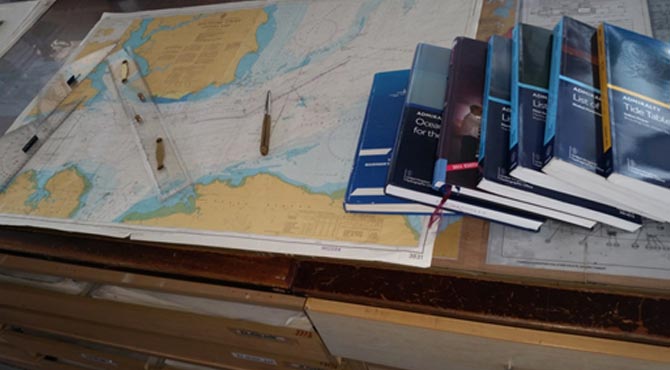

Figure 1 - Adequate and up to date charts and publications for the intended voyage

Master

Master or senior ship officer to provide pre-job briefing and on-the-job training to junior officers preparing the passage plan.

Master should supervise the passage planning, by reviewing and approving the passage plan.

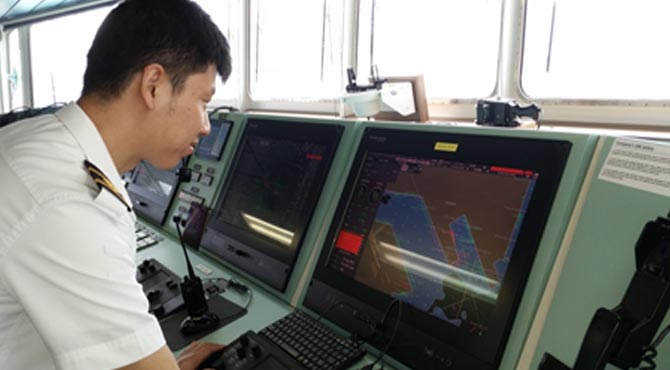

Figure 2 - Master supervising the preparation of passage plan

Execution

Prior to vessel departure, all adequate and up to date charts and publications for the intended voyage should be provided on board.

If the vessel is out at sea without adequate charts and publications for the intended voyage, the vessel should arrange for the required charts and publications to be connected on board before proceeding to port.

ECDIS

In light of the phasing in of ECDIS, companies should familiarise themselves with the ECDIS requirements and make the necessary amendments to their SMS.

Simple reminder signs can be placed on the unapproved ECDIS to remind OOWs that the ECDIS is only meant for training purposes and should not be used as primary means for navigation.

Figure 3 - Ship staff using ECDIS

References:

SOLAS regulation V/19 – Carriage requirements of shipborne navigational systems and equipment

SOLAS regulation V/27 – Nautical charts and nautical publications

SOLAS regulation V/34 – Safe navigation and avoidance of dangerous situations

IMO Resolution A.893(21) – Guidelines for voyage planning

STCW Code Part A Chapter II – Standards regarding the master and deck department