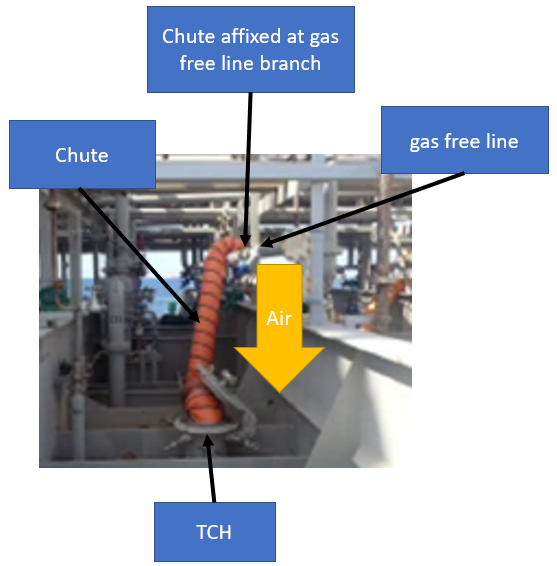

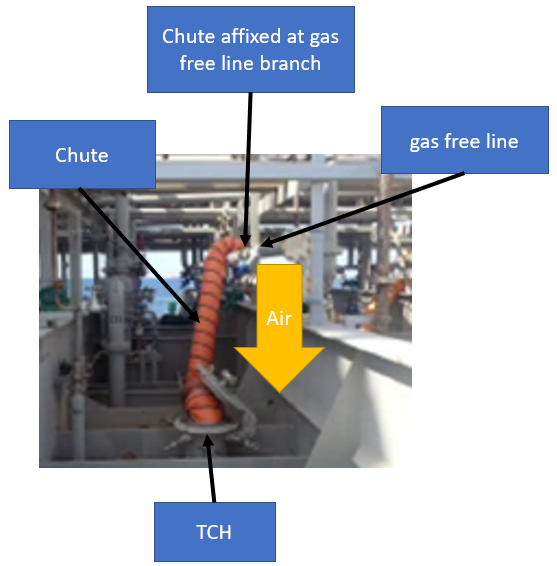

A chemical tanker (CT) gas free her cargo oil tanks (COT) by using a fixed gas-freeing fan which is connected to a main gas-freeing pipeline, which then branched to individual COT’s. A gas-freeing chute (“chute”) is affixed to the branch line and lowered into the COT that required gas freed through a tank cleaning hatch (TCH); see images below.

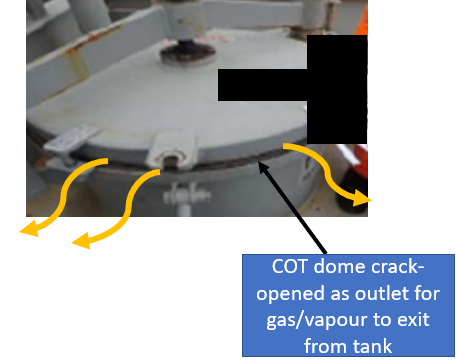

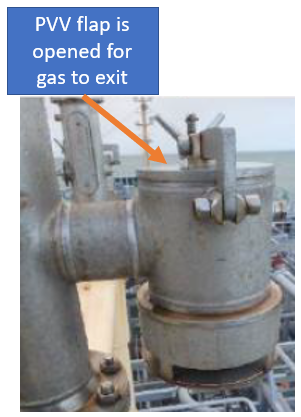

Fresh air from the fixed gas-freeing fan is supplied to COT through the chute. The air that is mixed with cargo vapour in the COT during gas freeing process exits through the COT’s pressure/vacuum valve (PVV) outlet and COT dome that is slightly opened.

Case study – fatality incident when shifting gas-freeing chute between cargo oil tanks

Chief Officer (CO) of CT drew out a duty roster for his crew to sequentially shifting chute between designated COT that were to be gas freed. During a 12-4 watch, at about 0208 hours LT, the 12-4 bridge lookout AB (AB) left the bridge to carry out the above duty without donning any personal protective equipment (PPE). Light relative wind at that time was from astern of CT. At about 0234 hours, bridge duty officer 2O called AB on the walkie-talkie but in vain. 2O then informed CO. CO found AB lying unconscious on the starboard main deck near xx COT at 0255 hours. Master and his crew carried out measures to assist and try to resuscitate the AB. Subsequently, the AB was declared dead.

Why did it happen?

Stipulated procedures as per the company’s Safety Management System (SMS) for gas freeing operation was not followed, i.e., the correct method to gas free COT in this case was to be through closed system where fresh air supplied by gas freeing fan will pass through cargo manifold connection thence enter the designated COT through drop line of that COT; and COT gas mixture will emit through PVV only. In this case, opening of TCH and COT dome caused gas mixture in COT to escape and accumulate around the vicinity. Gas mixture accumulation built up on deck over time as there was no air flow on deck due to the prevailing relative wind condition.

There was no risk assessment, permit to work, toolbox meeting and other applicable SMS requirements being carried out for the task in question, i.e., gas freeing operation and chute shifting. Relevant deck officers did not comply with the SMS including ensuring that appropriate PPE was available and used by their deck personnel when they instructed them to carry out the task in question.

Commentary

The SMS was in place for the task in question. However, it was not implemented. This includes correct method to gas free COT. Master and responsible ship personnel shall ensure safe operations and always follow appropriate SMS.