The Maritime Port and Authority of Singapore (MPA) is committed to maintain a quality flag status. We have seen over the past months more countries have begun to move forward into an endemic phase and easing up of restrictions after the two long years of combating the COVID-19 pandemic, which had impacted global shipping tremendously. We would like to take this opportunity to thank our ship owners, managers, and crew for your unwavering resilience and support through those challenging times.

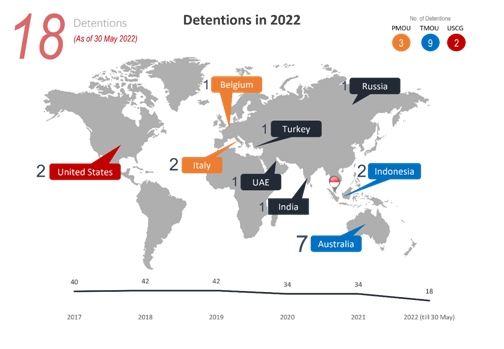

From start of the year till 30 May 2022, 18 SRS were detained under Port State Control (PSC) by the following authorities: Australia, Belgium, India, Indonesia, Italy, Russia, Turkey, United Arab Emirates and United States.

Notably, SRS has currently 9 detentions under the Tokyo MoU regime of which 7 of those detentions were concentrated in Australia. Under the Paris MoU regime, SRS has experienced 3 detentions, of which 2 were in Italy. There were also 2 detentions by USCG.

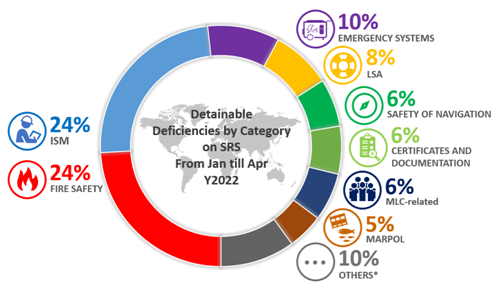

We have observed that most of the detentions were due to common PSC deficiencies which could have been avoided with proper and timely planned maintenance. A breakdown below highlights the deficiency categories:

*Others includes categories such as alarms, cargo operations, water/weathertight conditions, propulsion and auxiliary machinery and radio communications.

Call to Action

SRS operators are urged to arrange for their ships to be thoroughly inspected and to ensure that they are maintained in compliance with international rules and regulations, and to deal with any deficiencies promptly in accordance with the ISM Code. Deficiency which cannot be promptly rectified, Master shall report and apply dispensation from MPA (shipping@mpa.gov.sg) and the Classification Society. The Master shall also report the deficiency to the competent authority when the vessel is calling at a foreign port.

MPA have sent out an advisory email to draw attention to the increase in PSC detentions in Australia and have shared the detainable deficiencies observed in Australia. We have listed the detainable deficiencies experienced by SRS in Annex A to allow early preventive actions to be taken Ship owner and ship manager is requested to disseminate this information to key personnel in your office and on board your ships. Master is requested to share the information with all the crew on board.

We seek your cooperation and urgent attention on the matter in order to achieve our common objectives in maintaining our SRS as a quality flag.

Annex A

| No. | Country, Port | Deficiency Group | Detainable deficiencies |

| 1 | AUSTRALIA, ABBOT POINT | ISM CODE | Failure to adequately satisfy the requirements of the ISM Code, resulted from multiple Code 17 deficiencies related to Fire safety and lack of maintenance to shipboard equipment and structure. |

| 2 | AUSTRALIA, BRISBANE, QL | ISM CODE | Lack of maintenance onboard. The Safety Management System, as implemented onboard, fails to ensure effective implementation of element 10 of the ISM Code. |

| SMS as implemented does not ensure that critical shipboard operations as implemented effectively as evidenced by deficiencies. | |||

| FIRE SAFETY | ER fire damper found defective. | ||

|

CARGO OPERATIONS |

63 instances of cargo being secured in excess of allowable lashing forces on departure from Melbourne to voyage to Brisbane. Lashing computer program has acceleration forces set to reduced. Manufacturer’s instructions advise that accelerations must always be set to standard. Departure Brisbane condition shows 66 containers stowed in excess of permissible lashing forces. | ||

| 3 | AUSTRALIA, DAMPIER, WA |

LIFESAVING APPLIANCES |

Rescue boat engine and its propulsion system not operational. |

|

FIRE SAFETY |

Engine room fire dampers defective. | ||

| 4 | AUSTRALIA, PORT HEDLAND, WA |

MARPOL ANNEX I |

Oily Water Separator defective. |

| 5 | AUSTRALIA, SYDNEY, NS |

EMERGENCY SYSTEMS |

Crew not familiar with procedure to manually connect emergency generator to emergency switchboard. |

| 6 | BELGIUM, ANTWERPEN |

LABOUR CONDITIONS, HEALTH |

Ventilation fan for emergency fire pump room (enclosed space) defective. |

|

FIRE SAFETY

|

Quick closing valve system for closing Fuel oil and Lub oil tanks from remote not fully operational. | ||

| Means of isolating the fuel supply and spill piping to Auxiliary engines not working. | |||

|

ISM CODE |

Failure to adequately satisfy the requirements of the ISM Code, resulted from multiple Code 17 deficiencies related to Fire safety and lack of maintenance to shipboard equipment and structure. | ||

| 7 | INDIA, VISAKHAPATNAM |

PROPULSION AND AUXILIARY MACHINERY |

Vessel is fitted with 3 Auxiliary Engines (AE), out of which one AE is not operational since Feb 2022 and unable to take on electrical load. |

|

FIRE SAFETY |

Engine room found full of fuel oil at various places such as exhaust trunks, purifier room, hot well, various pipes, engine room bilges etc. it is reported that oil overflowed from boiler safety valve. | ||

|

WATER/WEATHERTIGHT CONDITIONS |

Cargo hatch cover found holed at various places. | ||

|

LIFESAVING APPLIANCES |

Windshield for helmsman on lifeboat found obscured. Helmsman unable to see outside. | ||

| 8 | INDONESIA, TANJUNG PERAK/SURABAYA, JAVA |

EMERGENCY SYSTEMS |

Water ingress system defective. |

|

MARPOL ANNEX IV |

Sewage treatment plant defective. | ||

|

ISM CODE |

Lack of maintenance of the ship and equipment, ISM not implemented onboard. | ||

| 9 | INDONESIA, TANJUNG PRIOK |

CERTIFICATES AND DOCUMENTATIONS |

Work accident entries not properly recorded. |

| ISM CODE

|

ISM code failure by company responsibility and authority. | ||

| The company does not prioritize safety in cargo activities, use of old web slings. | |||

| Failure of Master's responsibility and authority. | |||

| CARGO OPERATIONS

|

Officer-in-charge of cargo operation are not familiar with cargo securing manual. | ||

| Intended cargo is not listed in cargo securing manual. | |||

| 10 | ITALY, LIVORNO | EMERGENCY SYSTEMS | Fire drills - Lack of training. Some crew member assigned as per master list for fire emergency unable to demonstrate that they are familiar with their duties. |

| 11 | ITALY, TARANTO | MARPOL ANNEX V | Excessive garbage retained onboard on main deck foredeck starboard side. |

| CERTIFICATES AND DOCUMENTATIONS, CREW CERTIFICATES | Overdue crew, beyond MLC allowable maximum period onboard. | ||

| In the Seafarer’s Employment Agreement (SEA) for a crew member in the crew list, missing required information relating to the date when the SEA was entered into. | |||

| A crew member has a different position of employment onboard: SEA stated a different rank, while as per crew list he is employed as AB. | |||

| EMERGENCY SYSTEMS | Emergency towing manual not updated as per ship's specifics: only one AB with CoC II-5 is present on board while as emergency towing procedure, it was listed that 6 crew members are involved on deck for handling ropes and operating mooring winches. | ||

| FIRE SAFETY | Fire doors (A-Class) required to be self-closing type in steering gear room and in galley, found not able to close properly. | ||

| Test of smoke detection system of fixed fire-fighting of cargo holds failed: control panel reports "Fault" alarm despite gas extraction system was running and there was no possibility to reset the system. | |||

| During testing of emergency fire pump, a major water leakage detected from hydrant located at forward mooring station port side. | |||

| Fire drill in the galley failed: Lack of training of the appointed crew members with emergency procedures and evaluation of scenario during the fire drill. The ship's cook was not familiar in the use of blanket, ventilation, and electrical power supply to be isolated. Portable VHF not used between team leader and fire team, procedure for evaluation temperature of door carried out by operator without remove gloves; furthermore, the fire team entered in the area affected by smoke and flames without proper firefighting procedure. | |||

| Fire dampers manually operated at the forecastle found corroded. | |||

| ISM CODE | Deficiencies marked ISM are objective evidence of a serious failure, or lack of effectiveness of implementation of the ISM Code. | ||

| LABOUR CONDITIONS, ACCOMMODATION | The extraction duct of the hood in galley needs a deep additional cleaning due to excessive fat residue inside. | ||

| Several chairs found broken or in poor hygienic condition (mess room rating, gym, crew cabins). | |||

| LABOUR CONDITIONS, HEALTH | No. 2 stern ropes and No. 1 foredeck spring have strands damaged or cut. | ||

| SAFETY OF NAVIGATION | BNWAS on navigation bridge panel reports following alarm: "POWER FAULT". | ||

| 12 | RUSSIAN FEDERATION, NOVOROSSIYSK | LIFESAVING APPLIANCES | Rescue boat - Float (Top) was damaged, temporary repaired, cracked and bulwark with minor cracks. |

| Rescue Boat engine and its propulsion system not operational. | |||

| ALARMS | Navigation lights alarm panel on bridge source failed. | ||

| SAFETY OF NAVIGATION | Magnetic compass liquid missing. | ||

| EMERGENCY SYSTEMS | Emergency fire pump not operational. | ||

| FIRE SAFETY | Ventilation funnels of superstructure cover rubber groove through corroded. | ||

|

13 |

TURKEY, MERSIN, ICEL | SAFETY OF NAVIGATION | Bridge Navigation Watch Alarm System (BNWAS) inoperative. |

| LIFESAVING APPLIANCES | Rescue boat engine is not working during the inspection. | ||

| EMERGENCY SYSTEMS | Emergency fire pump is not working during the inspection. | ||

|

14

|

UNITED ARAB EMIRATES, PORT RASHID | EMERGENCY SYSTEMS | Overdue planned maintenance. All Emergency equipment and critical machineries/devices are not in operation condition due to main engine and auxiliary are inoperative. |

| RADIO COMMUNICATIONS | All radio equipment such as GDMSS, VHF, EPIRB etc are inoperative due to lack of power in addition of overdue for annual service and maintenance and re-certification. | ||

| FIRE SAFETY | All fire-fighting equipment/appliances are overdue. | ||

| SAFETY OF NAVIGATION | All Navigational aids, such as radars, AIS, Gyro compass, Echo sounder, GPS, etc. are not in operational condition due to lack of power. | ||

|

15 |

UNITED STATES, CORPUS CHRISTI, TX | FIRE SAFETY | Quick closing valve for LSMGO service tank, which was currently in use, was intentionally blocked. |

|

16

|

UNITED STATES, LONG BEACH, CA | ISM CODE | Company did not take appropriate actions on identified non-conformities. |

| FIRE SAFETY | The main engine fuel oil daily service tank, quick closing valve was found with a disconnected pneumatic line rending the valve incapable of being closed from a remote location. | ||

|

The observation caps, from the sample extraction smoke detection system, on each line were found loose and unsealed. The smoke extraction system sample was being taken from the atmosphere of the local CO2 room, preventing accurate reading. |