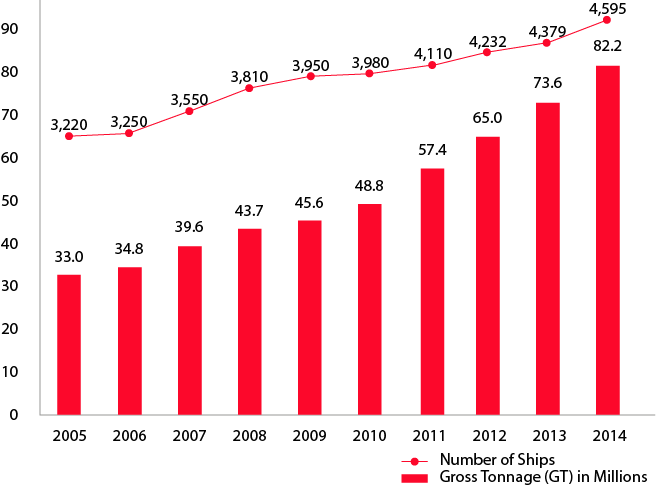

In 2014, the SRS grew by 8.6 million GT (11.7%) from 73.6 million GT to 82.2 million GT. The SRS continues to receive strong support from both existing as well as new shipowners to grow their fleet in Singapore. We see tonnage increases in all vessel segments, especially the offshore segment with more drill ships and exploratory rigs being registered. With a large fleet flying the Singapore flag, the SRS recognises that maintaining high shipping standards in terms of safety and security of vessels, as well as a low detention record in the major Port State Control (PSC) regimes, are critical to the reputation and attractiveness of the ship registry.

For the year of 2014, the Singapore Flag performed very well once again in Port State Control (PSC) - despite more stringent global PSC standards. Most Singapore ships were also found compliant during the PSC Concentrated Inspection Campaign (CIC) on STCW hours of rest and enforcement of Maritime Labour Convention requirements.

Nevertheless, there is still room for improvement as we are seeing more ships being detained in Australia and the United States due to ineffective or poor implementation of safety management systems (SMS). To achieve better performance and tackle undesirable trends, we will continue to engage our shipowners and companies, and encourage them to continuously improve on their SMS and the capability of their crews to perform their work effectively and consistently on board their ships. The resources and efforts required for this may not be very substantial, as illustrated in the case study below.

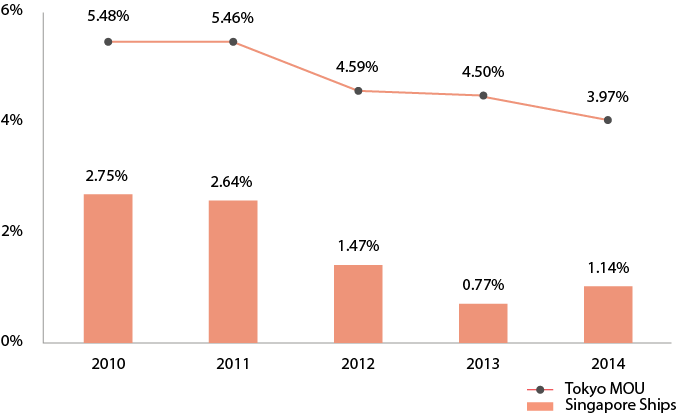

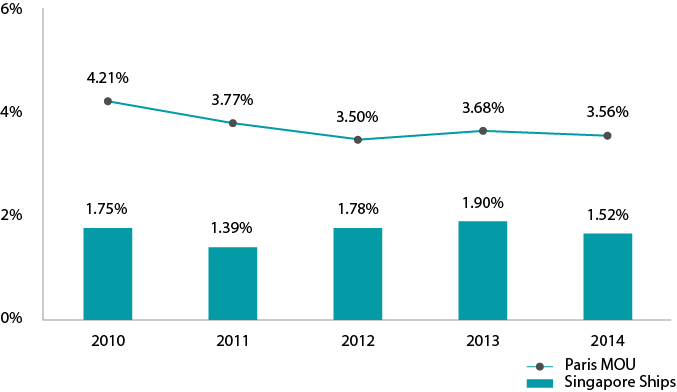

Tokyo MOU Regime

The annual detention ratio of Singapore ships in 2014 was 1.14% against the regime’s average of 3.97%, a slight increase compared to 2013 due to significantly more detentions in Australia, from 9 detentions in 2013 to 19 detentions in 2014.

There is an improvement in our 3-year rolling average detention ratio, which serves as a performance indicator to determine the position of flags in the PSC Black-Grey-White List. Singapore is ranked 4th out of 30 White List flags.

Tokyo MOU Detention Ratio

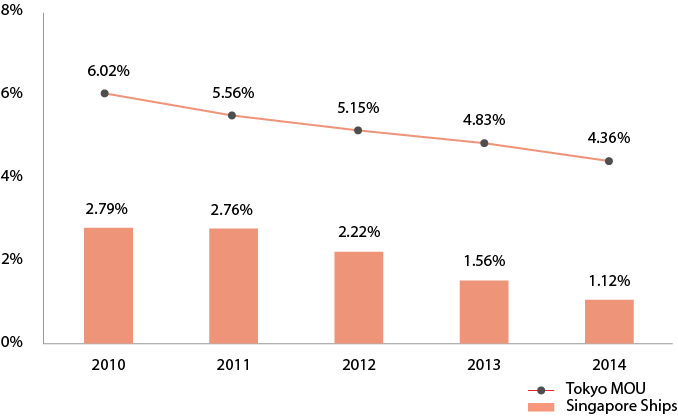

Tokyo MOU 3-Year Rolling Average Detention Ratio

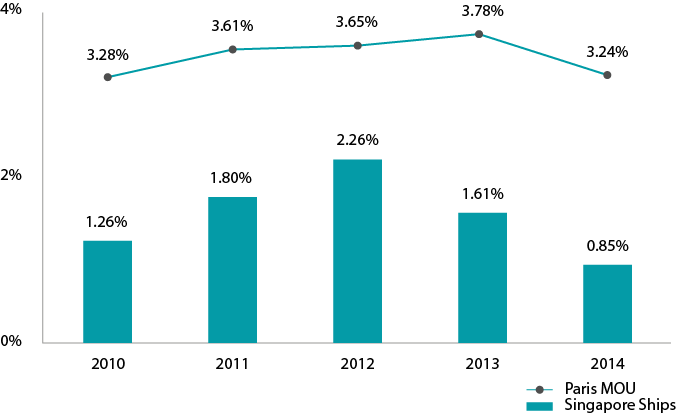

Paris MOU Regime

The annual detention ratio of Singapore ships in 2014 was 0.85 % against the regime’s average of 3.24%, an improvement from 1.61% in 2013.

There is also an improvement in our 3-year rolling average detention ratio. Singapore is ranked 14th out of 46 White List flags.

Paris MOU Detention Ratio

Paris MOU 3-Year Rolling Average Detention Ratio

United States Coast Guard (USCG)

A total of 7 Singapore ships were detained in the United States in 2014, a slight increase compared to 2013. The statistics for 2014 are not available yet.

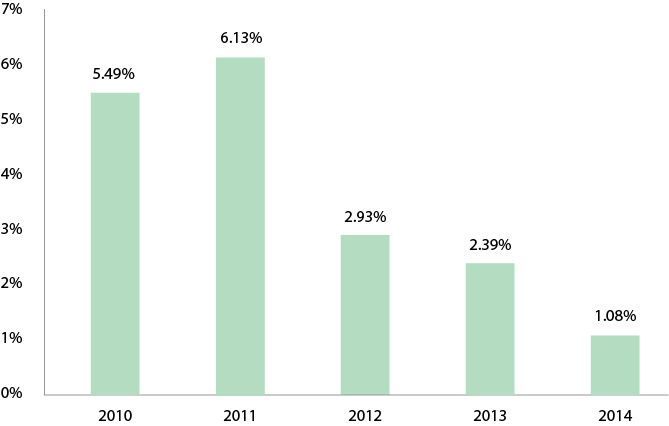

Flag State Control

MPA also conducts rigorous FSC inspections on Singapore ships to ensure they are well maintained and operated, and to monitor statutory services provided by the Recognised Organisations. The results were encouraging, as illustrated below.

The FSC detention ratio in 2014 was 1.08%, the lowest in the last five years despite the increase in number of FSC inspections (376 inspections in 2012 to 555 inspections in 2014).

This reflects the general improvement in the standard of Singapore ships.

FSC Detention Ratio

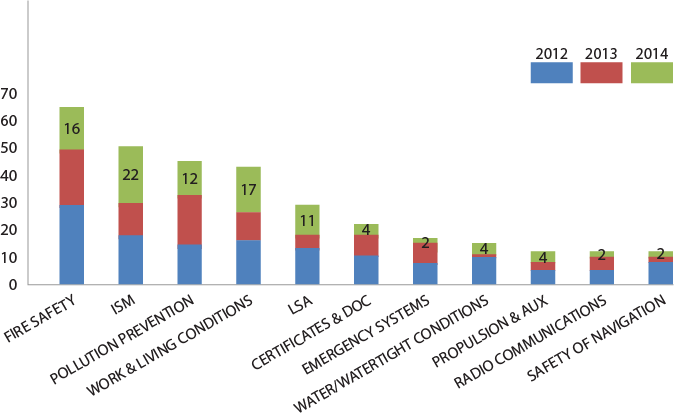

Most Common Causes of Ship Detentions

-

Under the Tokyo and Paris MOU regimes, most ship detentions were caused by:

Defective fire-dampers

Defective lifeboat on-load release gear and engine starting arrangement

Defective rescue boat launching and engine starting arrangement

-

ISM-related deficiencies such as:

Poor maintenance of safety equipment

Inappropriate voyage planning and use of outdated charts

Non-compliant discharge of sewage

Inadequate management and recording of seafarers’ hours of rest

In the United States, most ship detentions were caused by:

Fixed water-mist local application fire-fighting system not kept operationally ready (remote/automatic operation)

Unsatisfactory fire and abandon ship drills

Defective rescue boat engine

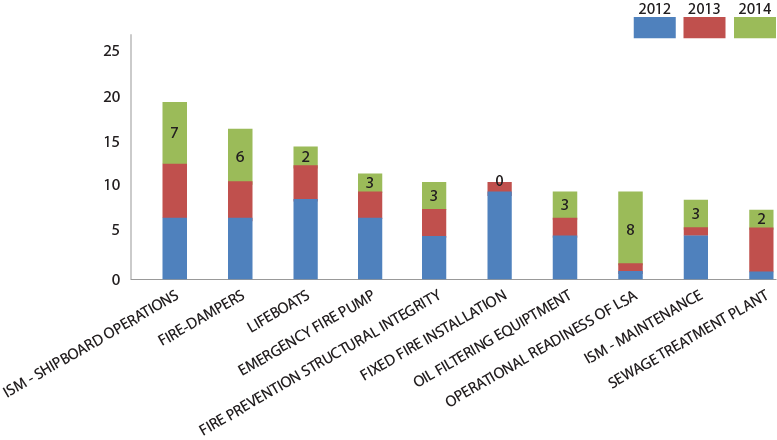

The detailed breakdown of all the PSC detention deficiencies for Singapore ships over the past three years are illustrated in the following two charts.

PSC Detention Deficiencies by Deficiency Group

PSC Detention Deficiencies by Specific Deficiency

Case Study on PSC Detention

Fixed water-mist local application fire-fighting system under SOLAS regulation II-2/10.5.6

A number of ships have been detained simply for not keeping their fixed water-mist local application fire-fighting systems in a state of operational readiness for automatic or remote release in case of a fire in the engine room.

Common deficiencies:

The local control panel of the system was inadvertently set on manual/local mode of operation.

The fresh water or sea water supply valve for the system was shut off.

This system is a relatively new requirement for Category A machinery spaces of cargo ships of 2000 gross tonnage and above, and built on or after 1 July 2002; in addition to having the usual fixed fire-extinguishing system for total flooding of the engine room. It is meant for extinguishing local fires at the main or auxiliary engine, boiler, incinerator and fuel oil purifiers without having to shut down the engine, evacuate personnel or seal the spaces. In periodically unattended machinery spaces, this system must be able to release automatically and manually. In automatic mode, the system will be released immediately when two fire detectors are activated. The system can also be manually released from inside and outside the protected spaces (e.g. engine control room and the bridge). In Unmanned Machinery Spaces (UMS) ships, if the system is not kept on automatic mode, the fire may spread quickly and be out of control before the crew can manually release the system.

Companies and ship’s crews were not always aware or did not pay attention to ensure that the fixed local application fire-fighting system is kept ready at all times for automatic operation in case of a fire. They have not incorporated the SOLAS requirements and manufacturer’s recommendations into their SMS procedures, instructions and checklist, and did not apply them during inspection, testing and maintenance of this system on their ships. The crew may forget to reset the system to automatic mode after carrying out testing and maintenance. In one case, the engineers ignored the warning sign at the control panel and intentionally isolated the system out of unfounded fear that the system may be accidentally released and cause damage to electrical equipment.

Simple and Actionable Corrective Actions:

Getting the job done right the first time and every time!

Drawing from the lessons learnt here, companies should review and update their SMS procedures, instructions and checklists for inspection, testing and maintenance of fire safety system, and familiarise their crew to ensure that they are aware of the company’s policy and mandatory requirements, and are applying the requirements when carrying out the work on their ships.

Clear warning signs and physical barriers (e.g. plastic shield) can be placed permanently at the control panel of the system to remind the crew to always keep the system on remote/automatic mode.

Adopt a Permit-To-Work and Lock out/tag out system when carrying out maintenance on fire safety and critical systems on board ships.

Ensure that such work is always supervised by senior ship officers.

Require ship officers and duty personnel to pay close attention to checking of the condition and status of the fire safety and critical systems during their daily rounds on ships.

References:

SOLAS regulation II-2/10.5.6 – Fixed local application fire-fighting systems

MSC.1/Circ.1387 – Revised guidelines for the approval of fixed water-based local application fire-fighting systems for use in category A machinery spaces

ISM Code section 10.3 – Maintenance of the ship and equipment